The bedding part must be leveled and a transition layer with a thickness of about 30 cm and a maximum particle diameter of 20 mm of composite geomembrane must be laid. Similarly, a filter layer should be laid on the membrane, followed by a protective layer. The periphery of the membrane should be tightly combined with the impermeable layer of the bank slopes on both banks. The connection between the impermeable membrane and the anchor groove is determined based on the allowable contact permeability gradient between the membrane and the concrete. Polyvinyl chloride and butyl rubber films can be well adhered to the concrete surface using adhesives or solubilizers, so the embedded length can be appropriately shorter. Due to the inability of the polyethylene film to adhere to the concrete surface, the length of the embedded concrete shall be at least 0.8m.

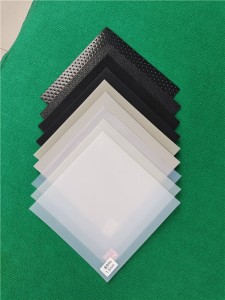

Geomembrane is a geosynthetic material with extremely low water permeability. In order for the membrane to play its due role in seepage prevention, in addition to requiring that the membrane itself be impermeable, attention should also be paid to the construction quality of laying the impermeable membrane.

1. Connection between the impermeable membrane and the surrounding boundary. The impermeable membrane must be tightly combined with the surrounding boundary. During construction, an anchor groove can be excavated to connect the foundation and bank slope.

If the foundation is a shallow sand gravel permeable layer, the sand gravel should be excavated until it is rich in rock, and then a concrete base should be poured to fix the geomembrane in the concrete. If the foundation is an impermeable clay layer, an anchor trench with a depth of 2m and a width of about 4m can be excavated. The geomembrane is placed in the trench, and then the clay is densely backfilled. If the foundation is a deep permeable layer of sand and gravel, geomembrane can be used to cover it for seepage prevention, and its length is determined based on calculation.

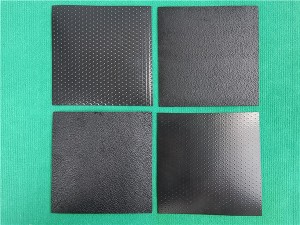

The contact surface between the impermeable membrane and the supporting material should be as smooth as possible to prevent the membrane from losing its impermeable effect by being punctured on the slope. Otherwise, a fine grained thermal layer should be provided to protect the film from damage.

3. Connection of the impermeable membrane itself. The connection methods of impermeable damp film can be summarized into three types, namely, bonding method, welding method, and vulcanization method. The selection depends on the different raw materials of impermeable film, and the impermeability of all connection joints should be checked. Composite geomembrane should be used to prevent leakage due to poor joint connection.

Post time: May-02-2023