-

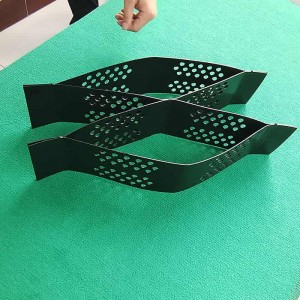

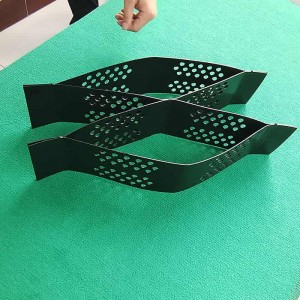

Plastic Geocell

Plastic geocell is a new type of geosynthetic material. It is a cell with a three-dimensional mesh structure made of high-molecular polymer sheets welded by rivets or ultrasonic waves. When using, unfold it in a grid shape and fill the loose materials such as stone and soil to form a composite material with an overall structure. The sheet can be punched or printed according to customer requirements to enhance its lateral water permeability and increase the friction and bonding force with the foundation material.

-

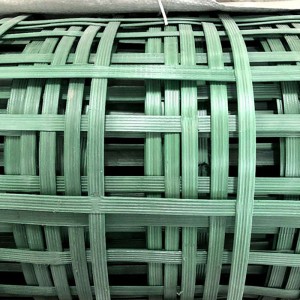

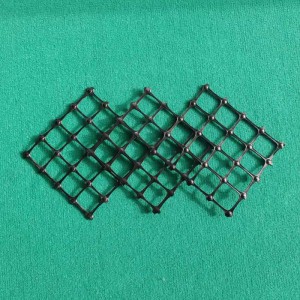

PP weld geogrid PP

PP weld geogrid is a new type of environmentally friendly building material that is reinforced with reinforced fibers in polyethylene and polypropylene tensile tapes, and then welded into a “#” structure. PP welded geogrid is an upgraded product of traditional steel-plastic geogrid, which improves the shortcomings of traditional geogrids such as low peeling force, easy cracking of welding spots, and little anti-side shift.

-

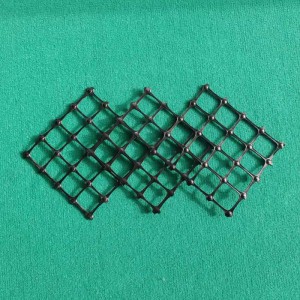

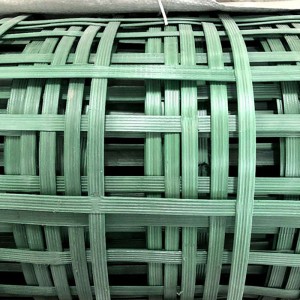

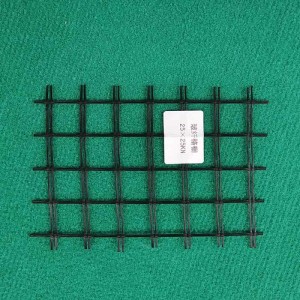

Steel-plastic composite geogrid

Steel-plastic composite geogrid is made of high-strength steel wire wrapped by HDPE (high-density polyethylene) into high-strength tensile belt, then weld the tensile belts together tightly by ultrasonic welding. Different mesh diameters and different quantity of steel wire are used to change the tensile strength according to the needs of different projects.

-

Warp knitted polyester geogrid

Warp knitted polyester geogrid is using high strength polyester fiber as raw material which is warp knitted bi-directionally and coated with PVC or butimen, which is known as “fiber reinforced polymer”. It is widely applied to the soft soil foundation treatment as well as the reinforcement of and roadbed, embankment and other projects to improve the quality of the project and reduce the cost of the project.

-

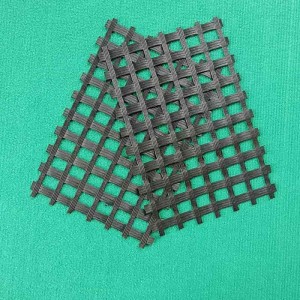

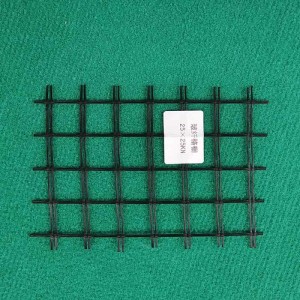

Uniaxial tensile plastic geogrid

Using high molecular polymer and nano-scale carbon black as the main raw materials, it is produced by extrusion and traction process to form a geogrid product with uniform mesh in one direction.

Plastic geogrid is a square or rectangular polymer mesh formed by stretching, which can be uniaxial stretching and biaxial stretching according to the different stretching directions during manufacture. It punches holes on the extruded polymer sheet (mostly polypropylene or high-density polyethylene), and then performs directional stretching under heating conditions. The uniaxially stretched grid is made by stretching only along the length of the sheet, while the biaxially stretched grid is made by continuing to stretch the uniaxially stretched grid in the direction perpendicular to its length.

Because the polymer of the plastic geogrid will be rearranged and oriented during the heating and extension process during the manufacture of the plastic geogrid, the bonding force between the molecular chains is strengthened, and the purpose of improving its strength is achieved. Its elongation is only 10% to 15% of the original sheet. If anti-aging materials such as carbon black are added to the geogrid, it can make it have better durability such as acid resistance, alkali resistance, corrosion resistance and aging resistance.

-

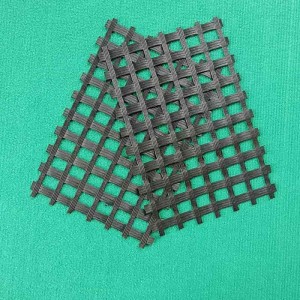

Biaxial tensile plastic geogrid

Using high molecular polymer and nano-scale carbon black as the main raw materials, it is a geogrid product with uniform vertical and horizontal mesh size produced by extrusion and traction process.

-

Glass fibre geogrid

It is a mesh structure material made of GE fiber as the main raw material, using advanced weaving process and special coating treatment process. It can improve the overall performance and is a new and excellent geotechnical substrate.