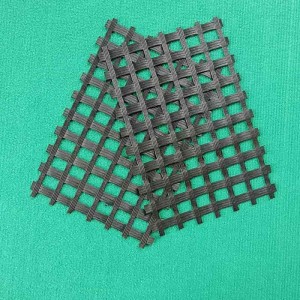

Uniaxial tensile plastic geogrid

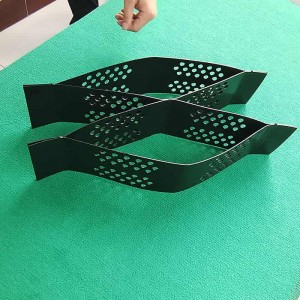

One-way geogrid

One-way geogrid is formed by extruding high molecular polymer into a thin plate, punching a regular mesh, and then longitudinally stretching. Long oval mesh integral structure. This structure has quite high tensile strength and tensile modulus, especially our company's products have a high early stage (elongation rate of 2%--- 5% ) tensile strength and tensile modulus. Provides the ideal force bearing and diffusion interlock system for the soil. The product has high tensile strength (>150Mpa) and is suitable for various soils. It is a widely used reinforcement material.

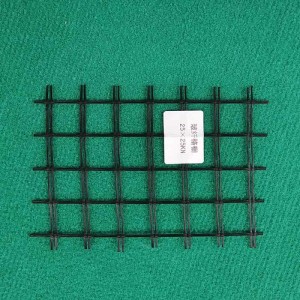

Product Description

Using high molecular polymer and nano-scale carbon black as the main raw materials, it is produced by extrusion and traction process to form a geogrid product with uniform mesh in one direction.

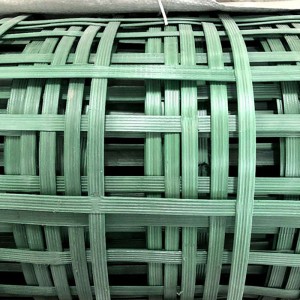

Product Specification:

TGDG35, TGDG50, TGDG80, TGDG120, TGDG160, TGDG260, TGDG300 etc., the width is 1~3meters.

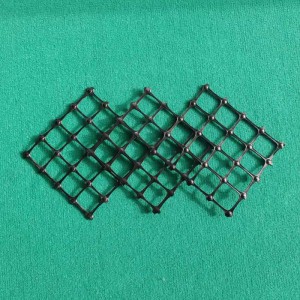

Product Features:

1. Strengthen the roadbed, improve stability and bearing capacity, and can withstand greater alternating loads;

2. Prevent the deformation and cracking of the subgrade caused by the loss of subgrade materials;

3. Improve the filling capacity of the retaining wall and save the engineering cost.

Application Scenarios

1.roadbed reinforcement of highways, municipal roads, railways, airstrips, etc. as well as dam reinforcement of rivers and sea dams;

2.Fencing of orchards, vegetable fields, livestock, land, etc.;

3.Reinforced engineering of soil retaining walls of expressways, municipal roads, railways, airstrips, rivers dams and sea dams.

Product Parameters

GB/T17689--2008 “Geosynthetics- Plastic Geogrid” (One way geogrid)

|

Product Specification |

Tensile Strength (Kn/m) |

Tensile strength with 2% Srain (Kn/m) |

Tensile strength with 5% srain (KN/m) |

Nominal Elongation ,% |

|

TGDG35 |

35.0 |

>10.0 |

22.0 |

≤10.0 |

|

TGDG50 |

>50.0 |

>12.0 |

28.0 |

|

|

TGDG80 |

>80.0 |

>26.0 |

48.0 |

|

|

TGDG120 |

>120.0 |

>36.0 |

>72.0 |

|

|

TGDG160 |

>160.0 |

>45.0 |

90.0 |

|

|

TGDG200 |

200.0 |

>56.0 |

>112.0 |