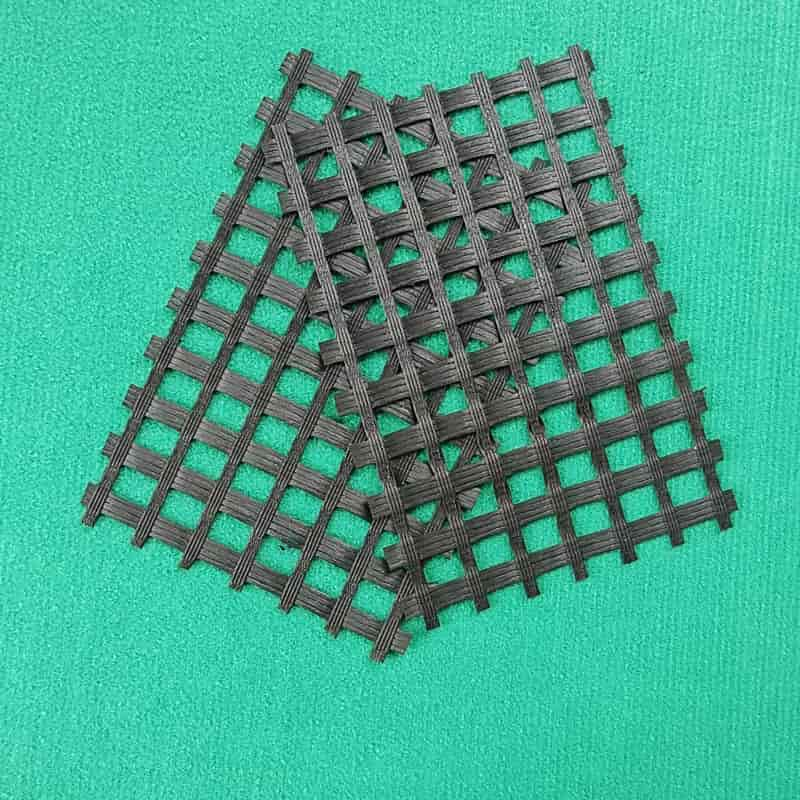

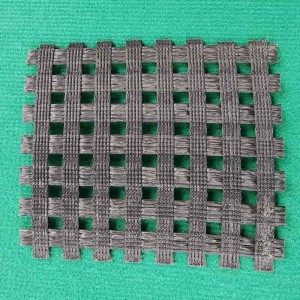

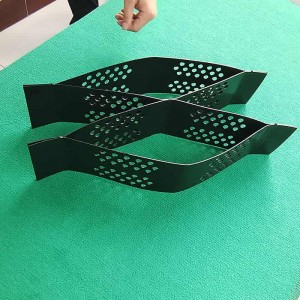

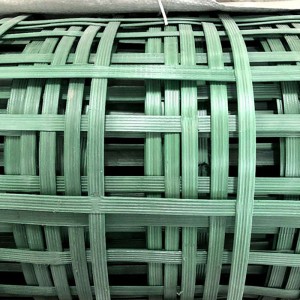

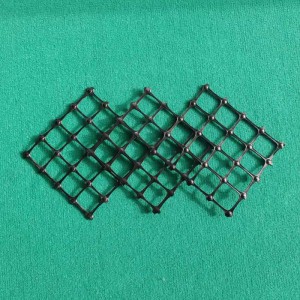

Warp knitted polyester geogrid

Product Description

Product Features:

1. High tensile strength,

2. High tear strength,

3. Strong binding force with soil gravel.

Application Scenarios

Reinforcement of soft soil foundations such as roads, railways and water conservancy.

1. For railway ballast protection: due to train vibration, wind and rain, the ballast is lost. Wrapping the ballast with a geogrid can prevent the loss of the ballast and improve the stability of the roadbed;

2. For railway retaining walls: geogrids are used for reinforcement of retaining walls on the edge of railways, such as platforms and cargo platforms in railway stations, which can prolong the service life and reduce maintenance costs;

3. For the reinforcement of retaining walls: adding geogrid beside the road and in the vertical retaining wall can improve the bearing capacity of the retaining wall;

4. For the foundation of the abutment: the foundation of the abutment is generally easy to sink downwards, and the phenomenon of car jumping occurs. Laying a geogrid under the foundation of the abutment can improve the bearing capacity and stabilize the abutment.

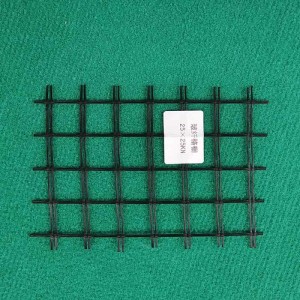

Product Parameters

JTT480-2002 “Geosynthetics in the traffic engineerings -Geogrid”

| limit tensile strength per metre length along the width direction KN/m | tension fracture strength per metre length along the width direction % |

limit tensile strength per metre length along the width direction after 100 freezing and thawing cycle KN/m |

tension fracture strength per metre length along the width direction after 100 freezing and thawing cycle % |

Grid Space mm |

Freezing-Resistance ℃ |

Limit Peel Force at Sticky or Weld Point N |

|

|||||

|

Longitudinal |

Landscape |

Longitudinal |

Landscape |

Longitudinal |

Landscape |

Longitudinal |

Landscape |

Longitudinal |

Landscape |

|||

|

GSZ30-30 |

30 |

30 |

≤3 |

≤3 |

30 |

30 |

≤3 |

≤3 |

232 |

232 |

-35 |

≥100 |

|

GSZ40-40 |

40 |

40 |

≤3 |

≤3 |

40 |

40 |

≤3 |

≤3 |

149 |

149 |

-35 |

≥100 |

|

GSZ50-50(A) |

50 |

50 |

≤3 |

≤3 |

50 |

50 |

≤3 |

≤3 |

220 |

220 |

-35 |

≥100 |

|

GSZ50-50(B) |

50 |

50 |

≤3 |

≤3 |

50 |

50 |

≤3 |

≤3 |

125 |

125 |

-35 |

≥100 |

|

GSZ60-60(A) |

60 |

60 |

≤3 |

≤3 |

60 |

60 |

≤3 |

≤3 |

170 |

170 |

-35 |

≥100 |

|

GSZ60-60(B) |

60 |

60 |

≤3 |

≤3 |

60 |

60 |

≤3 |

≤3 |

107 |

107 |

-35 |

≥100 |

|

GSZ70-70 |

70 |

70 |

≤3 |

≤3 |

70 |

70 |

≤3 |

≤3 |

137 |

137 |

-35 |

≥100 |

|

GSZ80-80 |

80 |

80 |

≤3 |

≤3 |

80 |

80 |

≤3 |

≤3 |

113 |

113 |

-35 |

≥100 |

|

sSZ100-100 |

100 |

100 |

≤3 |

≤3 |

100 |

100 |

≤3 |

≤3 |

95 |

95 |

-35 |

≥100 |