Short-filament geotextiles have excellent filtration, barrier, reinforcement and protection effects, high tensile strength, good permeability, high temperature resistance, freezing resistance, aging resistance, and corrosion resistance. Geotextiles are divided into woven geotextiles and non-woven geotextiles.

Non-woven geotextiles: Non-woven geotextiles are made of filaments or short fibers laid out into a mesh through different equipment and technologies. After acupuncture and other technologies, different fibers are intertwined with each other, entangled with each other and fixed to make the fabric. Normalization makes the fabric soft, plump, solid, and stiff, so as to achieve different thicknesses to meet application requirements. It can also have excellent deformation adaptation ability, excellent surface drainage ability, soft surface and multi-void, excellent friction coefficient, can increase the adhesion ability of soil particles, etc., can prevent fine particles from being eliminated by preventing the loss of particles. The remaining moisture is removed, and the appearance is soft and has excellent maintenance ability. According to the length of the filament, it is divided into filament non-woven geotextile or short filament non-woven geotextile. They can play an excellent role in filtering, blocking, reinforcement, protection, etc., is a widely used geotechnical composition materials. The tensile strength of filament is higher than that of short filament, which can be selected and used according to specific requirements.

Woven geotextile (reinforced geotextile): woven geotextile is composed of at least two groups of parallel yarns (or flat yarns), one group is called warp along the longitudinal direction of the loom (the direction of fabric travel), and the other group is called warp. Lateral placement is called weft. Different weaving equipment and techniques are used to interlace the warp and weft yarns into a cloth shape, which can be woven into different thickness and compactness according to different application ranges. Strong tensile strength (longitude is greater than latitude), with excellent stability. Woven geotextiles are divided into two categories: reinforced geotextiles and non-reinforced geotextiles based on weaving technology and the use of warp and weft. The warp tensile strength of reinforced geotextiles is much greater than that of ordinary geotextiles. Woven geotextiles are usually used in practice and are intended to be reinforced for geotechnical projects. The main function is to reinforce and strengthen, and it has the function of plane barrier and maintenance. It does not have the function of plane drainage and can be selected according to the specific application purpose.

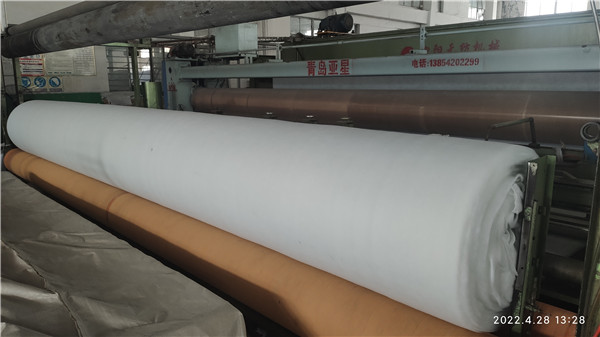

Staple fiber needle-punched geotextile: a kind of right and wrong weaving and industrial fabrics. It is made of polyester bent staple fibers with a fiber fineness of 6-12 denier and a length of 54-64 mm as the raw material. After the process of opening, finishing, messing (short fibers are intertwined with each other), laying (standardized entanglement and fixing), needle punching and other production technologies of non-woven production equipment, it is made into cloth. It is mainly used in the reinforcement of railway subgrades, the maintenance of highway pavements, the protection of sports halls and dikes, the barriers of hydraulic construction, tunnels, coastal mudflats, reclamation, environmental protection and other projects.

Post time: Feb-10-2023