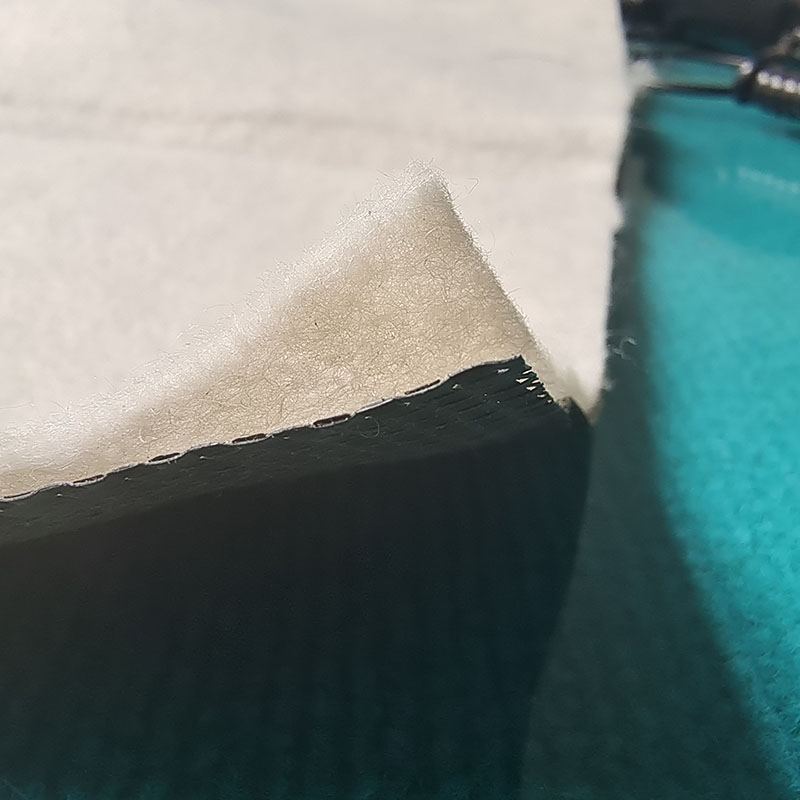

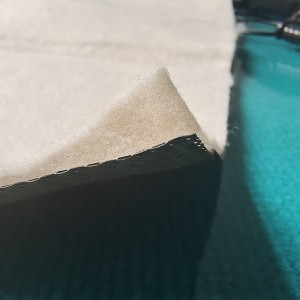

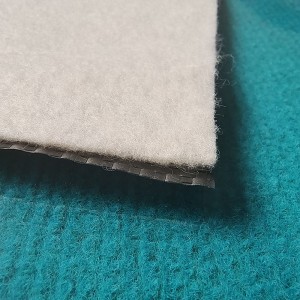

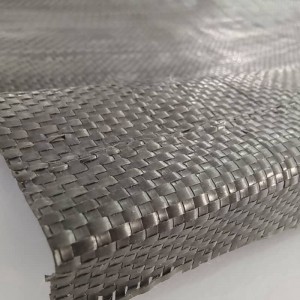

plastic woven film yarn geotextiles

Plastic flat woven geotextile

Woven geotextile is a geosynthetic material woven from polypropylene and polypropylene ethylene tape as raw materials. It is widely used in geotechnical engineering such as water conservancy, electric power, harbor, highway and railway construction.

1. High strength Due to the use of plastic flat wire, it can maintain sufficient strength and elongation in dry and wet conditions.

2. Corrosion resistance It can resist corrosion for a long time in soil and water with different pH.

3. Good water permeability There are gaps between the flat wires, so it has good water permeability.

4. Good anti-microbial properties, no damage to microorganisms and moths.

5. Convenient construction Because the material is light and soft, it is convenient for transportation, laying and construction.

Product Introduction

Product Specification:

The gram weight is 90g/㎡~400g/㎡; the width is 4~6meters.

Product Features:

Light weight, high strength, small elongation, good integrity, and convenient construction; it has the functions of reinforcement, separation, drainage, filtration and blocking.

Application Scenarios

1. Water conservancy engineering: seawall, river embankment, and lake embankment standard projects; embankment protection projects, water diversion irrigation projects; anti-seepage and risk elimination and reinforcement of reservoir projects ; enclosure and reclamation projects; flood control projects.

2. Highway engineering: soft foundation reinforcement treatment; slope protection; pavement anti-reflection joint structure layer; drainage system; green isolation belt.

3. Railway engineering: railway foundation bed reinforcement project; embankment slope reinforcement layer; tunnel lining waterproof and drainage layer; geotextile drainage blind ditch.

4. Airport engineering: runway foundation reinforcement; apron foundation and pavement structure layer; airport road and drainage system.

5. Power plant engineering: basic engineering of nuclear power plant; ash dam engineering of thermal power plant; hydropower station engineering.

Product Parameters

GB/T17690-1999 “Geosynthetics- plastic woven film yarn geotextiles”

|

No. |

Item |

20-15 |

30-22 |

40-28 |

50-35 |

60-42 |

80-56 |

100-70 |

|

1 |

Vertical breaking strength,KN/m≥ |

20 |

30 |

40 |

50 |

60 |

80 |

100 |

|

2 |

Horizontal breaking strength,KN/m≥ |

15 |

22 |

28 |

35 |

42 |

56 |

70 |

|

3 |

Vertical and Horizontal Breaking elongation,%≤ |

28 |

||||||

|

4 |

Trapezoid tearing strength(vertical), kN ≥ |

0.3 |

0.45 |

0.5 |

0.6 |

0.75 |

1.0 |

1.2 |

|

5 |

Bursting strength, kN ≥ |

1.6 |

2.4 |

3.2 |

4.0 |

4.8 |

6.0 |

7.5 |

|

6 |

Vertical Permeability Coefficient, cm/s |

10-1~10-4 |

||||||

|

7 |

Equivalent pore size O95, mm |

0.08-0.5 |

||||||

|

8 |

Mass per unit area, g/m2 |

120 |

160 |

200 |

240 |

280 |

340 |

400 |

|

Allowable deviation value, % |

±10 |

|||||||