Short polypropylene staple nonwoven geotextiles

Product Description

Product Specification:

The gram weight is 100g/㎡~500g/㎡; the width is 1~6 meters, and the length is according to customer needs.

Product Features:

The physical and mechanical properties are 2 to 3 times higher than that of conventional products and the specific gravity is low for the same weight;

Excellent acid and alkali resistance, good hot-melt adhesion, and strong wear resistance.

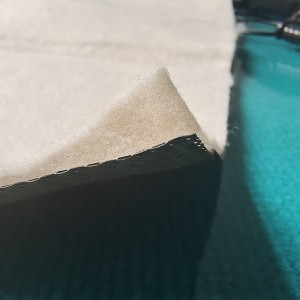

Application Scenarios

Polypropylene needle-punched non-woven geotextiles are mainly used for the sliding layer between the CRTSII slab ballastless track and the beam surface of the passenger dedicated railway, and the isolation layer between the CRTSII slab ballastless track and the friction plate, and can also be widely used in expressways, railways, ports, airports, coastal mudflats, reclamation, environmental protection and other engineering fields.

Product Parameters

JTT 992.1-2015 “Geosynthetics in highway engineerings - Geotextiles Part 1: Short polypropylene staple of nonwoven geotextiles”

| No. | Item | Unit | Indicator | ||||||||||||

| 110 | 130 | 150 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 | 1200 | ||||

| 1 | The quality deviation per unit area, % | % | ±5 | ±5 | ±5 | ±6 | |||||||||

| 2 | Thickness | mm | ≥1.0 | ≥1.2 | ≥l.5 | ≥1.8 | ≥2.4 | ≥2.8 | ≥3.2 | ≥3.6 | ≥4.0 | ≥4.4 | ≥5.2 | ≥6.0 | |

| 3 | Breaking strength | Vertical | kN/m | ≥7 | ≥9 | ≥10 | ≥13 | ≥20 | ≥26 | ≥32 | ≥40 | ≥48 | ≥52 | ≥60 | ≥70 |

| Horizontal | |||||||||||||||

| 4 | Breaking elongation | Vertical | % | 40-80 | |||||||||||

| Horizontal | |||||||||||||||

| 5 | CBR Bursting strength | kN | ≥1.5 | ≥1.8 | ≥2.0 | ≥2.5 | ≥3.8 | ≥4.5 | ≥5.8 | ≥7.0 | ≥8.5 | ≥9.0 | ≥11.5 | ≥14 | |

| 6 | trapezoid tearing strength | Vertical | N | ≥160 | ≥180 | ≥220 | ≥300 | ≥400 | ≥500 | ≥600 | ≥700 | ≥85O | ≥l 000 | ≥1 200 | ≥1 400 |

| Horizontal | |||||||||||||||

| 7 | Effective pore size (Dry Screening) O90 | mm | 0.08-0.2 | ||||||||||||